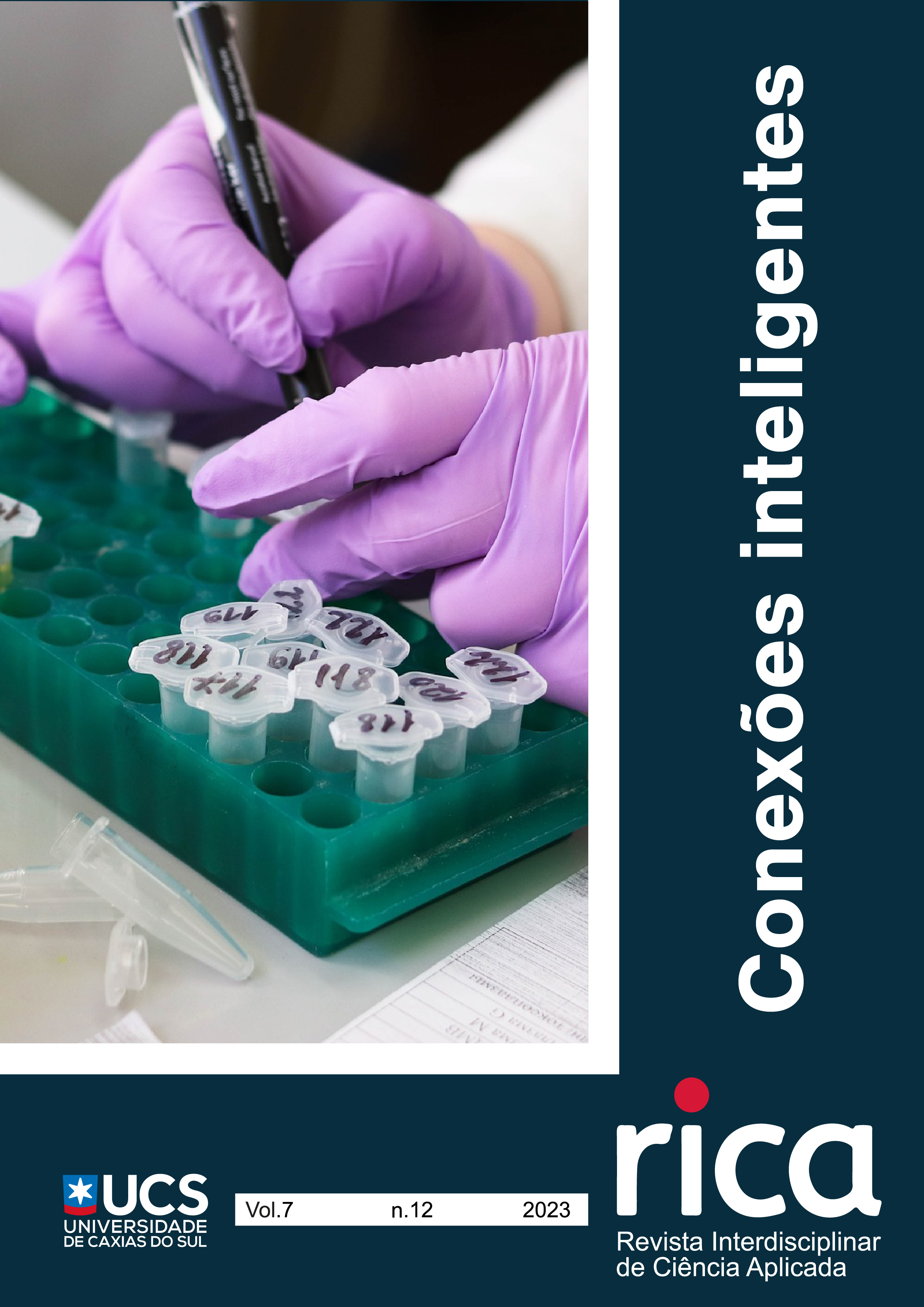

Technical Evaluation of the Use of Biocidal Additives in Cementitious Composites

DOI:

https://doi.org/10.18226/25253824.v7.n12.09Keywords:

PortuguêsAbstract

Although cementitious composites have several applications, they still have limitations in their characteristics, including biodeterioration, due to the action of microorganisms. In order to improve this condition, zinc oxide (ZnO) was added as a biocide additive, in order to add better performance against the action of microorganisms, in addition to pozzolanic materials, rice husk ashes, which, together with the biocide additive, they can improve the mechanical resistance and the absorption of water by capillarity of the cementitious composite. In this study, the properties of cementitious composites with the addition of zinc oxide (ZnO) and rice husk ash (RCA) were evaluated in the fresh and hardened state. Traces were developed, varying the additions, in grams of material, of ZnO at 0%, 5%, 10%, 15% and 20%, in addition to the fixed 10% of CCA, 0.042% of superplasticizer and their w/w ratio. c of 0.5. To evaluate the performance of the cementitious composites, tests were carried out on consistency, resistance to compression and traction in bending, total and partial water absorption by capillarity, in addition to the visual analysis of the biocidal properties. There was great fragility in the samples with the incorporation of the biocide additive, demonstrating a drop in their workability, a reduction in resistance by up to 97% for traction in flexion at 7 days and by up to 98% for compression at 7 days, a water absorption per capillarity three times greater than the reference, as well as a delay in the curing time of the materials. The visual analysis showed little variation in the defined time.

References

ANANDARAJ, S. et al. (2022). Materials Today: Proceedings, Effects of using white flour, zinc oxide and zinc ash as an admixture in mortar and concrete. 52 (1), 5. http://dx.doi.org/10.1016/j.matpr.2021.11.447.

ALUM, A. et al. (2008) Cement and Concrete Composites , Cement-based biocide coatings for controlling algal growth in water distribution canals, 30(9), 8. Retirado de https://www.sciencedirect.com/science/article/abs/pii/S0958946508000693.

ATKINS, Peter; JONES, Loretta; LAVERMAN, Leroy. (2018). Oxford: Bookman. Princípios da Química: questionando a vida moderna e o meio ambiente. Local de publicação: Bookman.

BEZERRA, Izabelle M. T. et al. (2011). Aplicação da cinza da casca do arroz em argamassas de assentamento. Revista Brasileira de Engenharia Agrícola e Ambiental, Campina Grande, 15(1), 6. Retirado de https://www.scielo.br/j/rbeaa/a/xBdfQfDCZTTtpBgSt9yMvdD/?lang=pt&format=pdf#:~:text=A%20cinza%20produzida%20pela%20queima,utilizada%20tamb%C3%A9m%20como%20material%20pozol%C3%A2nico.

CARASEK, Helena. (2017). Materiais de Construção Civil e Princípios de Ciência e Engenharia de Materiais. Patologia das Argamassas de Revestimento. Local de publicação: Ibracon. Retirado de https://ecivilufes.files.wordpress.com/2011/03/patologias-em-argamassa.pdf.

HOPPE FILHO, J. et al. (2017). Atividade pozolânica de adições minerais para cimento Portland (Parte I): Índice de atividade pozolânica (IAP) com cal, difração de raios-X (DRX), termogravimetria (TG/DTG) e Chapelle modificado. 22 (3), 5. Rio de Janeiro. Retirado de https://www.scielo.br/j/rmat/a/sYkhMxmJKjxHQB5FfvdxJLk/abstract/?lang=pt.

KAWABATA, Celso Yoji; SAVASTANO JUNIOR, Holmer; SOUSA-COUTINHO, Joana. (2012). Ciência e Agrotecnologia. Rice husk derived waste materials as partial cement replacement in lightweight concrete., 36 (5), 11. Local de publicação: FapUNIFESP (SciELO). http://dx.doi.org/10.1590/s1413-70542012000500010.

KHALAF, Mohammed A. et al. (2021) Construction And Building Materials. Effect of nano zinc oxide and silica on mechanical, fluid transport and radiation attenuation properties of steel furnace slag heavyweight concrete, 274. Local de publicação: Elsevier BV. http://dx.doi.org/10.1016/j.conbuildmat.2020.121785.

LANGARO, Eloise Ap.; et al. (2010). Influência do óxido de zinco nos tempos de pega e nas resistências à compressão do cimento portland e do cimento aluminoso. 1 (1), 7. Canela. Retirado de https://silo.tips/queue/influencia-do-oxido-de-zinco-nos-tempos-de-pega-e-nas- resistencias-a-compressao?&queue_id=-1&v=1681672284&u=MjgwNDozMGM6M TczMjoyZjAwOjk4MzA6YzcwOjhmOWM6ODg4OQ==.

LI, Xiaoying; LI, Jun; LU, Zhongyuan; CHEN, Jiakun. (2021). Properties and hydration mechanism of cement pastes in presence of nano-ZnO. Construction And Building Materials, 289 (1), 123. Local de publicação: Elsevier BV. http://dx.doi.org/10.1016/j.conbuildmat.2021.123080.

LISBOA, Ederval de S. et al. (2017). Materiais de Construção: Concreto e Argamassa. Local de publicação: LTC.

LIU, S.; OUYANG, J.; REN, J. (2020). Construction and Building Materials, Mechanism of calcination modification of phosphogypsum and its effect on the hydration properties of phosphogypsum-based supersulfated cement., 243 (1), 12.

NBR 9778, 2005. Argamassa e concreto endurecidos – Determinação de absorção de água, índice de vazios e massa específica. Rio de Janeiro.

NBR 13276, 2016. Argamassa para assentamento e revestimento de paredes e tetos – Determinação do índice de consistência. Rio de Janeiro.

NBR 13279, 2005. Argamassa para assentamento e revestimento de paredes e tetos – Determinação da resistência à tração na flexão e à compressão. Rio de Janeiro.

NBR 15259, 2005. Argamassa para assentamento e revestimento de paredes e tetos – Determinação da absorção de água por capilaridade e do coeficiente de capilaridade. Rio de Janeiro.

NBR 15575-1, 2021. Edificações Habitacionais - Desempenho - Parte 1: Requisitos Gerais. Rio de Janeiro.

POUPELLOZ, E.; GAUFFINET, S.; NONAT, A. (2020). Cement and Concrete Research, Study of nucleation and growth processes of ettringite in diluted conditions, 127 (1), 10. Retirado de https://www.sciencedirect.com/science/article/abs/pii/S0008884619306726.

QIU, Liangsheng et al. (2020). Construction and Building Materials, Antimicrobial concrete for smart and durable infrastructures: A review., 260. China. Retirado de https://www.sciencedirect.com/science/article/pii/S0950061820324612.

QUÍMICA, Brasile. (2023). Óxido de Zinco 99%. São Paulo. Retirado de https://www.basilequimica.com.br/produtos/oxido-de-zinco-99/.

VAQUERO, J.M. et al. (2016). Sciencedirect: Cement and Concrete Composites, Development and experimental validation of an overlay mortar with biocide activity., 74 (9), 11, Retirado de https://www.sciencedirect.com/science/article/pii/S095894651630508X?casa_token=WMcZJL20doAAAAAA:YgE9xMAOZsR3fA3aHsxihq0jAOhSabB7q2VP9WfrhH9apvRUyrgwcFyRwfmDIAUd1Xs8vGW9l9A.

VISALI, C.; PRIYA, A.K.; DHARMARAJ, R. (2021). Materials Today: Proceedings. Utilization of ecofriendly self-cleaning concrete using zinc oxide and polypropylene fibre., [S.L.], 37 (1), 4. Local de publicação: Elsevier BV. http://dx.doi.org/10.1016/j.matpr.2020.06.309.

VOICU, Georgeta; TIUCA, Georgiana-Andreea; BADANOIU, Alina-Ioana; HOLBAN, Alina-Maria (2022). Journal Of Building Engineering, Nano and mesoscopic SiO2 and ZnO powders to modulate hydration, hardening and antibacterial properties of portland cements. 57 (1), 104, Local de publicação: Elsevier BV. http://dx.doi.org/10.1016/j.jobe.2022.104862.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ândria Deves Alves, Vinício Cecconello

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors keep the copyright and cede to the journal the right of publishing first. Published works are licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license, allowing the sharing of the work with recognition of the authorship and initial publication in this journal.